NanoSØRB™ is a Ni/ZnO nanowire-based catalytic adsorbent, which removes sulfur from natural gas, syngas, fuel gas, LPG, gasoline, kerosene, and diesel. The technology operates at lower pressure, temperature, and hydrogen-to-oil ratio than other processes. The adsorbent is capable of removing H2S, COS, mercaptans, disulfides and thiophenes, and achieving TOTAL Sulfur specification of < 1 ppm or lower, if needed.

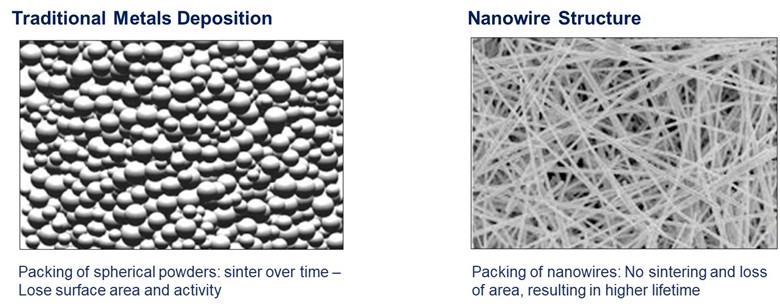

The spent media is regenerable using air for oxidizing the adsorbed sulfur into SO2. The regeneration gas can be routed to a Claus unit for final conversion into elemental sulfur. It is important to note that NanoSØRB™ is not conventional hydrodesulfurization (HDS). There is no H2S production during the desulfurization process in NanoSØRB™. Ni extracts the S from the sulfur contained hydrocarbon species and Zn converts the sulfur into ZnS. The fundamental advantage of using nanowires as opposed to nano-spheres, is that nanowires retain significantly high surface area throughout the operation and activation. In contrast, nanospheres are prone to sintering upon activation. Due to the ideal crystal surface in nanowires, the media displays high selectivity and reactivity. Hence, the operating parameters required for desulfurization are significantly less than conventional hydrodesulfurization.

Fig 1: Nanowires vs Nanospheres: Sintering