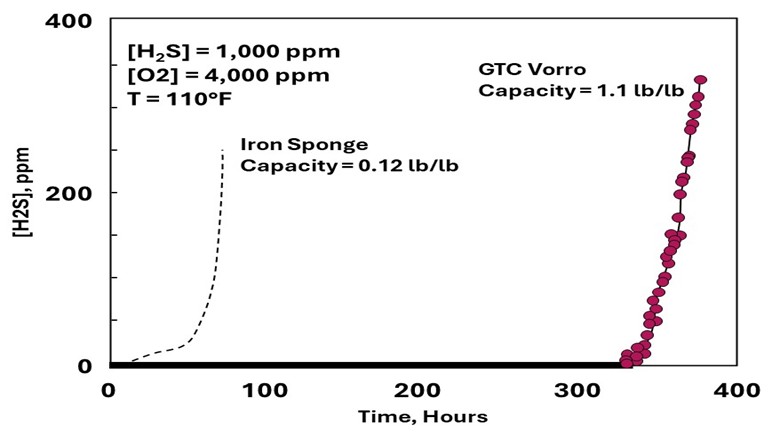

SweetTreat-O™ is a proprietary mixed metal oxide adsorbent, which was developed to have ultra-high H₂S removal capacity. SweetTreat-O™ can achieve 110-120 wt% sulfur loading. The media has a highly porous structure, which results in low pressure drop across the system. Further, due to the usage of certain metals in the formulation, the adsorbent exhibits fast adsorption kinetics as opposed to slow kinetics in traditional iron-oxide adsorbents.

The adsorbent is deployed in a system of two identical fixed bed scavengers in “lead/lag” configuration, which allows maximum operation flexibility. A small amount of air is introduced in the system, to maintain a certain O₂/H₂S ratio via an air blower to provide oxygen for inline regeneration of the adsorbent. When the adsorbent in the lead scavenger approaches the end of life and needs to be replaced, this vessel can be taken offline for adsorbent changeout; and the lag scavenger will keep operating without any compromise on the product specification. The fundamental chemistry behind adsorption is as follows:

M-O + H₂S M → S + H2O (Adsorption)

M-S + 1/O₂ M → O + elemental S (Inline Regeneration)

[where M denotes the metal content in the media]

Due to the porosity of the media, elemental sulfur deposits inside the pores, while the gas is flowing on the outside of the pore across the active sites. Hence, the system does not experience high pressure drop as the sulfur is removed. Eventually, the elemental sulfur blocks the active sites leading to media becoming spent. The spent media is classified as Non-Hazardous Commercial Waste and can be disposed of at a landfill.

Fig 1: Media capacity comparison with iron sponge