Joseph C. Gentry

GTC Vorro Technology

Introduction

The petrochemical industry is pressured. Environmental regulations dominate investment budgets, and often take the top priority in operating expenditures. Mandates on compliance rule over all else, and must be adhered to as a license to operate regardless of the logic or cost/benefit analysis. The Gas Processing Industry faces some of the same challenges, and has found different ways for managing H2S that are prudent to consider in the downstream industry.

The current buzz of attention is about anything ‘green’. For steam cracker plants, this is mainly reflected in a) taking unconventional feeds or recycled polymers or bio-fuels, or b) making products that are recyclable or environmental-friendly. But, traditional issues such as waste reduction and energy efficiency remain important as well. This paper is a sequel to the article Zero Sulfur in Refineries, which prompts some re-thinking about sulfur management in downstream industry based on practices learned in the Gas Processing Industry.

The Sulfur Conundrum

Issues with sulfur are mainly related to crackers processing naphtha or heavier feedstocks, as ethane and LPG feedstocks contain little sulfur.

On a macro scale, sulfur comes in from:

- Liquid hydrocarbon feedstock. This includes H2S that has been sequestered by triazine in the loading and transporting of naphtha by barge.

- Furnace tube pre-sulfiding

- Chemical additives

- Pre-sulfiding agents for catalysts

Sulfur leaves the cracker plant in:

- Products [Pyrolysis Gas Oil (PGO), Pyrolysis Fuel Oil (PGO), and Pyrolysis Gasoline (pygas), including C4 and C5 cuts]

- Waste Caustic

- Soluble salts in process waste-water

As in refineries, sulfur is not our friend. There are many ill-effects from sulfur in steam cracking plants, including:

- Catalyst poison

- Equipment corrosion

- Severe health hazard

- Interferences with process chemistry

- Specification issues in finished products

- Process line freezing in the Cold Box

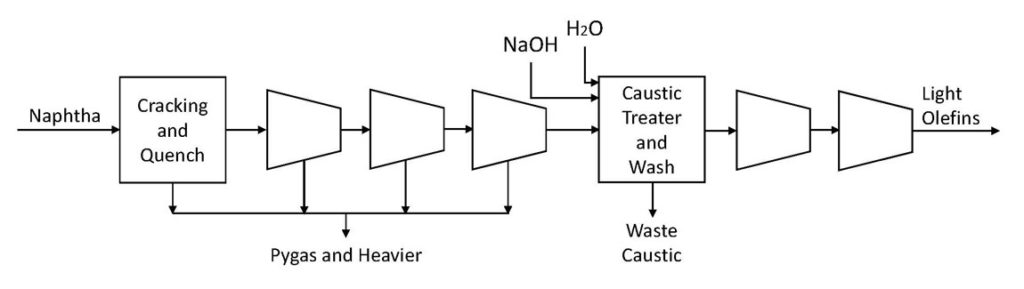

Let’s look at the most important means for removing sulfur, which is the caustic treater and wash tower. This is usually positioned after the third stage of charge gas compression, and has the purpose to remove H2S and CO2 before continuing into the Cold Fractionation section of the cracker. At this point in the process, some of the sulfur is in the form of H2S resulting from the severe thermal conditions at the cracker furnace. CO2 derives from decomposition of oxygenated products in the cracker hot section. In any case, both of these need to be removed to ppm level of concentration.

Figure 1. Caustic treatment of acid gases

In the caustic treater, H2S reacts with NaOH to form NaSH and a few other sulfonated products. Caustic is used in excess to ensure that no H2S leaves to go further downstream unconverted; then water washed to remove remaining sodium hydroxide. The stream typically goes to wet air oxidation to reduce the COD, and is neutralized with hydrochloric acid or sulfuric acid, which creates water-soluble salts from the acid and base.

The other dominant acid gas, CO2, reacts with caustic to form sodium carbonates, which entail the same further treatment.

What causes headaches? Almost universally, cracker operators will note that waste caustic handling is a chronic nuisance they wish would go away. The operation is prone to complications, with many operational steps required that do not directly relate to producing ethylene.

There is:

- Cost of the fresh caustic

- Red oil generated in the caustic treater, which needs disposal and causes hydrocarbon yield loss

- Cost of wet air oxidation to reduce the COD

- Cost of acid to neutralize the waste caustic

- Cost of wastewater treatment or ultimate disposal of waste caustic

- Environmental impact of sodium sulfate salts and sodium carbonate added to wastewater

Figure 2: Waste Caustic Processing

Anything that can be done to reduce the load on the caustic wash system will be advantageous for the cracker operator by improving the safety and environmental impact in the waste water treatment system. Additionally, there will be OPEX savings associated with less waste disposal.

Heavy Sulfur Species

One method for reducing the operating costs in the caustic treater is to eliminate the loading that comes from the heavy sulfur species. In the Hot Section fractionation of the cracker, the sulfur species are segregated by their boiling points into PFO, PGO, and the C5+ pyrolysis gasoline fraction.

The PGO and PFO leave the system directly with their sulfur, and are not the topic for discussion here.

The sulfur components in the pygas are hydrotreated into H2S in 2-stage hydrotreatment units. The H2S is recycled back to the charge gas ahead of the caustic wash tower for removal by conventional means. At this point in the process, the recycle gas stream is free of impurities except the H2S, which can be removed by adsorption in a SweetTreatTM 1 vessel or direct treatment system. The acid gases in this recycle would therefore bypass caustic treating and have a proportional reduction in operating costs. H2S from the pygas of naphtha crackers represents a significant quantity of the total hydrogen sulfide that must be removed.

Figure 3. Alternative to H2S Removal from Pygas Hydrotreatment

C4, and C5 Cuts – Sulfur removal in the C4 and C5 cuts uses a different method, as these are carbonyl or sulfide species and not reactive with basic amines or caustic. The raw cuts of these heavy olefins are not subject to hydrotreatment on account of the need to preserve the butadiene, isoprene, and hydrocarbon resin reactives. Other strategies using selective adsorption of sulfur species can be used to remove these trace components.

Conclusion

The sulfur problem in petrochemical plants can be solved piece by piece, eventually bringing about notable improvements. One item is introduced here:

- Use an adsorption system or direct treatment of H2S on the pygas hydrotreater offgas to intercept the H2S that would otherwise go to the caustic wash system. The load on the caustic treatment system is reduced and there is a proportional reduction in OPEX along with reduced waste.

Other solution pathways will address the fundamentals of caustic treating altogether, along with specific sulfur-reducing adsorbents and techniques for the various sulfur species.

Looking beyond compliance requirements and operating costs, ESG scores play an important role in the cracker’s viability. Reducing waste products from the caustic treater will demonstrate environmental commitment and establish the cracker operator as a leader that is sensitive to environmental issues.

Reference

1SweetTreat™ is a system which removes H2S from gas streams using adsorption or direct conversion of H2S into sulfur or sulfur products.