Resources and Articles by GTC Vorro Technology

Sulfur Removal: An Energy Saving Enabler

GTC Vorro’s Joseph C. Gentry and Rahul Khandelwal shares insights on advancements in sulfur removal. Highlighting innovative solutions like NanoSØRB™ and SweetTreat-O™, this piece explores how cutting-edge adsorbents and catalysts are transforming desulfurization processes, improving energy efficiency and reducing emissions across various industrial applications.

Novel Sulfur Removal Pathways to Aid Energy Reduction & Decarbonization

GTC Vorro Technology’s Rahul Khandelwal was recently featured at ME-TECH, presenting on “Novel Sulfur Removal Pathways to Aid Energy Reduction and Decarbonization.”

His talk explore how refiners and petrochemical operators are leveraging advanced sulfur removal technologies to tackle key challenges in decarbonization, energy efficiency and emissions control. From innovative adsorbents and catalysts to smarter strategies for fuel gas and diesel desulfurization, the session offered pracical insights for driving operational gains.

A Novel Approach for Sulfur Removal from Coal or PetCoke Derived Syngas

India’s rapidly evolving energy landscape has opened doors for groundbreaking technologies that leverage the nation’s coal reserves. One area of focus is coal gasification, which converts coal into clean syngas for energy and chemical production. At the heart of this advancement lies efficient sulfur removal from syngas, a critical step to ensuring environmental compliance and operational efficiency.

GTC Vorro’s Alok Saxena’s recent presentation at the 15th World PetroCoal Congress sheds light on innovative solutions addressing this critical challenge.

SweetTreat-O™: Revolutionizing H₂S Removal with High-Capacity, Regenerative Adsorbent Technology

SweetTreat-O™ is a proprietary mixed metal oxide adsorbent, which was developed to have ultra-high H2S removal capacity. SweetTreat-O™ can achieve 110-120 wt% sulfur loading. The media has a highly porous structure, which results in low pressure drop across the system. Further, due to the usage of certain metals in the formulation, the adsorbent exhibits fast adsorption kinetics as opposed to slow kinetics in traditional iron-oxide adsorbents.

NanoSØRB™: Revolutionary Ni/ZnO Nanowire Catalyst for Ultra-Low Sulfur Removal

NanoSØRB™ is a Ni/ZnO nanowire-based catalytic adsorbent, which removes sulfur from natural gas, syngas, fuel gas, LPG, gasoline, kerosene, and diesel. The technology operates at lower pressure, temperature, and hydrogen-to-oil ratio than other processes. The adsorbent is capable of removing H2S, COS, mercaptans, disulfides and thiophenes, and achieving TOTAL Sulfur specification of < 1 ppm or lower, if needed.

BTX Direct™ Naphtha Dearomatization Process Brochure

Discover GTC Vorro’s BTX Direct™ Naphtha Dearomatization Process. Boost olefin yields, lower costs and simplify operations with our innovative, high-capacity solvent technology. Download the full brochure below!

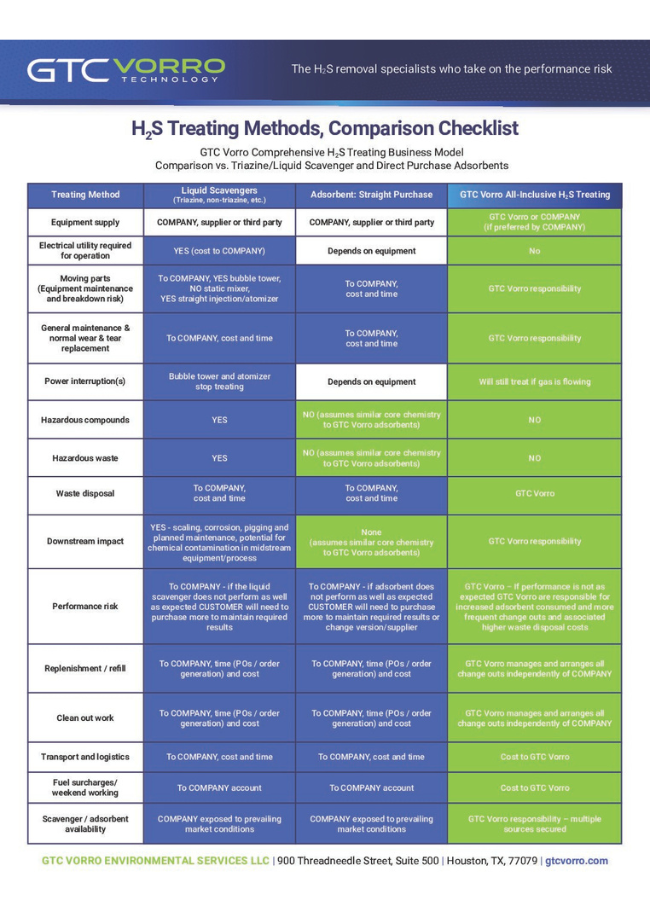

H₂S Treating Methods, Comparison Checklist

GTC Vorro Technology, a turnkey provider of environmental services and process technologies to oil and gas, refining and petrochemical companies, has released an H₂S Treating Methods Comparison Checklist to help industry professionals make informed decisions about their H₂S removal strategies.

Designed to streamline decision-making, this checklist helps organizations select the optimal solution for their unique operational needs. Unlike traditional solutions, GTC Vorro takes on the performance risk, ensuring reliable results without burdening clients with operational uncertainties. This customer-focused approach reflects GTC Vorro’s commitment to providing sustainable, cost-effective technologies that adapt to dynamic industry demands and operational needs.

Optimizing petroleum naphtha

As featured in Hydrocarbon Processing, January 2024 issue

Hydrocarbon Processing’s January edition featured an article by GTC Vorro Technology Director of Technology and Engineering, Zhepeng Liu. The article, titled ‘Optimizing petroleum naphtha,’ highlighted the significant improvements that can be achieved in petroleum naphtha.

“One of the interesting dimensions of chemical engineering is the management of processing operations related to the molecular composition of the raw material. Petroleum naphtha is one area where significant improvements can be achieved by changing the sequence of processing steps or altering the general scheme of processing altogether to take advantage of the natural distributions of components.”

Zero Sulfur in Refineries

As featured in Engineering Practice, January 2022 issue

The refining industry is pressured. Environmental regulations dominate investment budgets, and often take the top priority in operating expenditures. Mandates on compliance rule over all else, and must be adhered as a license to operate regardless of the logic or cost/benefit analysis. The Gas Processing Industry faces some of the same challenges, and has found different ways to manage H2S that may be useful in the downstream refinery industry.

Zero Sulfur in Steam Cracker Plants

As featured in Engineering Practice, March 2022 issue

The petrochemical industry is pressured. Environmental regulations dominate investment budgets, and often take the top priority in operating expenditures. Mandates on compliance rule over all else, and must be adhered to as a license to operate regardless of the logic or cost/benefit analysis. The Gas Processing Industry faces some of the same challenges, and has found different ways for managing H2S that are prudent to consider in the downstream industry.

The current buzz of attention is about anything ‘green’. For steam cracker plants, this is mainly reflected in a) taking unconventional feeds or recycled polymers or bio-fuels, or b) making products that are recyclable or environmental-friendly. But, traditional issues such as waste reduction and energy efficiency remain important as well. This paper is a sequel to the article Zero Sulfur in Refineries, which prompts some re-thinking about sulfur management in downstream industry based on practices learned in the Gas Processing Industry.

BTX Gold™ Solvents

BTX Gold™ solvents are custom applied for BTX recovery from all sources of feed (catalytic reformate, pyrolysis gasoline, Coke Oven Light Oil, FCC gasoline, coker naphtha, straight run naphtha), and can replace solvents in liquid-liquid extraction or extractive distillation designs.